What led the companies to create these ad-hoc supply chains? What challenges did they face, and what supported them in their efforts? In an extensive study, experts from Kühne Logistics University conducted about 40 interviews with members of the Senior Management, Managerial Boards and Manufacturing Management of German companies.

Social responsibility and business continuity

“With previously unimaginable speed and agility, textiles manufacturers, chemical concerns and automotive suppliers created new supply chains virtually from scratch. They secured access to raw materials, identified new partners, and adapted their production processes in record time – and did it all despite the adverse conditions imposed by the corona lockdown,” summarizes Prof. Kai Hoberg. “We wanted to know: How was this possible in just a few weeks? And what are the takeaways for our normal business?”. As the interviews show, the companies had ample motivation: on the one hand a sense of social responsibility; on the other, massive pressure to compensate for financial losses in their core business and avoid having to let workers go.

Replacing standard processes with pragmatic solutions

This rapid restructuring was largely made possible by pragmatic solutions. For instance, many companies avoided standard processes, which involve test phases and certifications, in order to save valuable time. “In some cases, even major companies planned their production activities using Excel instead of SAP as usual,” reports KLU doctoral candidate Jasmina Müller.

Focus: Creativity, regional cooperation, direct communication

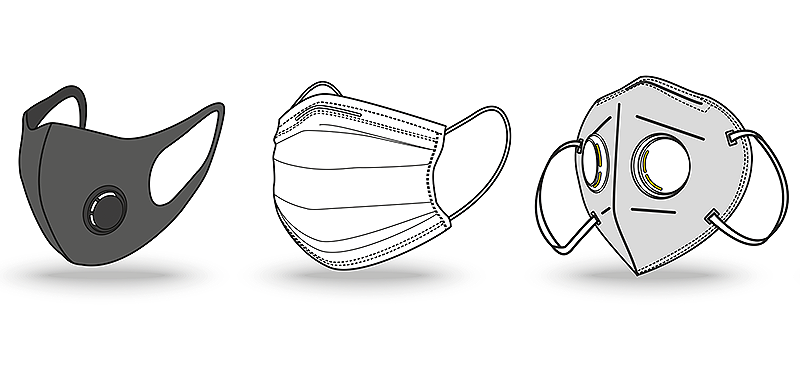

In addition, available resources were creatively used: for example, textile manufacturers used materials already on hand to produce face masks, while Managerial Board members’ chauffeurs used their working time to deliver disinfectant. Another new aspect was the regional focus for procurement and cooperation, in response to closed borders: “One company provided the machinery, a second delivered the fabric, and others sewed the masks,” Jasmina Müller explains. Last but not least, the value of direct communication became apparent. “Hierarchies were ignored, and CEOs contacted one another directly, not through their secretaries or staff. And in some cases, core teams were in contact round the clock.”

Challenges: Material shortages, uncertainty, teamwork

Material shortages were one of the greatest challenges (e.g. filter material, nose clips for masks, and bottles for disinfectant). In addition, the spread of the virus which determines the demand of medical supplies was impossible to predict. According to Jasmina Müller: “Since the demand was uncertain, the production planning changed on a daily basis.” At the same time, established team routines were disrupted. Many highly motivated employees were happy to put in overtime, while others found it difficult to work outside the limits of their standard processes.

The interview series was jointly developed and implemented by Prof. Kai Hoberg, Prof. Jan Fransoo and KLU doctoral candidate Jasmina Müller. A second wave of interviews is scheduled for the fall. Once the companies have gained a bit of perspective on this early phase of the crisis, the focus will be on how the new business has developed, and what companies have learned for the future.

Feedback from companies:

Social Responsibility

- We sell disinfectants at cost. We’re not trying to turn a profit from this pandemic. (CEO, chemical industry)

- We received requests from our subsidiary in Italy, asking if we could produce face masks. And of course we wanted to help. (Head of PPE, automotive industry)

- Forwarding companies contacted us and offered to distribute our disinfectant for free. (Head of Logistics, chemical industry)

Business Continuity

- We started producing face masks to survive the crisis. (Head of R&D, medical industry)

- It was important to secure liquidity. The production of face masks was an opportunity to generate sales. (Managing Director Global SC, fashion industry)

Replacing Standard Processes/Hands-on

- If we had started a normal product development process, we probably wouldn’t have been able to deliver the first masks until 2021. (Head of Global SCM, fashion industry)

- From Friday to Monday we developed the masks and planned production; on Monday we started producing them. (CEO, automotive industry)

- We did not certify our masks, so as to avoid getting lost in the administrative process. (Sales Manager, textile industry)

- Our purchasing manager simply got in his car and drove 150km to get the caps directly from the supplier. (Director Manufacturing, pharmaceuticals industry)

- The negotiations for the machine took place at a motorway rest stop. We brought some folding chairs and a folding table and just started talking. (COO, fashion industry)

Direct Communication

The normal communication lines are too long for such a situation. I just called the CEO at our supplier directly; if I had written an email, I would probably still be waiting on an answer now. (CEO, fashion industry)